The objective of this project is to create an API to control the parametric family developed in the project-1. As presented in the first project, the panels should expand themselves based on the required heat gains to be attained inside the building. To demonstrate this a sample building is created with curtain walls all around and the adaptive parametric family is loaded. The sample building is presented in Figure 1 and Figure 2.

the panels should adjust such that the solar radiation coming from the west and south sides should be minimized during the peak heating period. For this project, the adjusted for this panel is done for the peak heating period in the Houston, Tx, climate area. creation of the solar radiation database is explained below.

1. Incident solar radiation is obtained from the National Solar Radiation Database Compiled by the NREL.

2. The incident solar radiation is converted into transmitted solar radiation for south, east and west directions by the following equation.

G Transmitted = Total energy transmitted from the glazing area

G Incident = Total energy incident on the surface

F Trans = Transparency value of the glass

SC = Solar heat gain coefficient

F Refract = Refractive index of the glass

This equation is followed by Ecotect Software and it is taken from the training manuals.

The transmitted radiation on the surface for a particular direction is found by the azimuth angles given in the radiation database. Snapshot of the database is shown below.

3. In the next step, for each direction, the offset values for each directions are created based on the approximate solar transmittance to be allowed in those directions. The offset values will be approximate and used for a conceptual illustration purpose only.

For example, from morning 8 to 11, east side receives maximum light so the offset value is given 0.5 which means glazing is reduced by 50%. But the offset value is given zero for south and west directions because of the minimum radiation in those period of times. Offset value of 1 is given from 12 to 15 in south direction, which means that the glazing is closed to 0% to stop the radiation. In the next step, this radiation database is communicated to the geometrical model and it is explained in the next step.

5. The API is created by following the steps below:

a. accessing the geometry of the panels

b. get type parameters of the objects.

c. link the database to the type parameters of the panels

method of changing the offset of the panels through the API.

Basically, the pattern of the panels is determined for a particular month, day and time in the format of

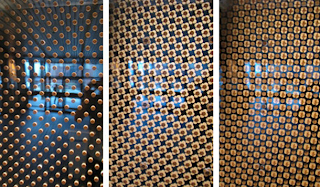

Month-Day-Time. April-1-12 is for Noon time on April 1st. This parameter should be changed for south, west, and east directions to visualize the pattern. Figure below illustrates that.

the panels should adjust such that the solar radiation coming from the west and south sides should be minimized during the peak heating period. For this project, the adjusted for this panel is done for the peak heating period in the Houston, Tx, climate area. creation of the solar radiation database is explained below.

1. Incident solar radiation is obtained from the National Solar Radiation Database Compiled by the NREL.

2. The incident solar radiation is converted into transmitted solar radiation for south, east and west directions by the following equation.

G Transmitted = Total energy transmitted from the glazing area

G Incident = Total energy incident on the surface

F Trans = Transparency value of the glass

SC = Solar heat gain coefficient

F Refract = Refractive index of the glass

This equation is followed by Ecotect Software and it is taken from the training manuals.

The transmitted radiation on the surface for a particular direction is found by the azimuth angles given in the radiation database. Snapshot of the database is shown below.

The transmitted radiation in the peak heating period from 12:00 PM to 17:00 is so high that the design requires low emission glazing to stop the heat gain. But, during the winter there might be a need to let the solar gain inside to the heat the space and the heat gain factor of the glass cannot be changed from summer to winter. so the glazing area is changed by altering the offset parameter to increase or decrease the heat gain factor of the curtain wall. Lets for instance, the solar transmission through the east side facade is 23% of the

of the incident solar radiation. Since east side solar gain will usually be not be high, the south side glazing can be adjusted to transmit 23% solar radiation similar to the east direction. This methodology is just taken as the quick process to see the panel configurations for various glazing area options and may not represent actual solar radiation analysis of the glazing system. One of the main motivations in doing this is that various configurations can be created for the complex fenestration systems and can be exported to the thermal and daylighting softwares to compare the most efficient one. 3. In the next step, for each direction, the offset values for each directions are created based on the approximate solar transmittance to be allowed in those directions. The offset values will be approximate and used for a conceptual illustration purpose only.

For example, from morning 8 to 11, east side receives maximum light so the offset value is given 0.5 which means glazing is reduced by 50%. But the offset value is given zero for south and west directions because of the minimum radiation in those period of times. Offset value of 1 is given from 12 to 15 in south direction, which means that the glazing is closed to 0% to stop the radiation. In the next step, this radiation database is communicated to the geometrical model and it is explained in the next step.

5. The API is created by following the steps below:

a. accessing the geometry of the panels

b. get type parameters of the objects.

c. link the database to the type parameters of the panels

method of changing the offset of the panels through the API.

Basically, the pattern of the panels is determined for a particular month, day and time in the format of

Month-Day-Time. April-1-12 is for Noon time on April 1st. This parameter should be changed for south, west, and east directions to visualize the pattern. Figure below illustrates that.